Fab Valve Sizes

NPS ½ FP to NPS 8 SP

½″ FP to 8″ SPFab Valve Connections

150#, 300#, 600#, NPT,

SW, butt weld, CustomFab Valve Configurations

On/Off, Vari-V Control,

Double Isolation & BleedFab Valve Temperatures

-50°C to 593°C

-58°F to 1100°FFab Valve Delivery

Based on size an

material availabilityFab Valve Quote

Click here to receive

a Fab Valve quote.

Fab Valve Downloads

Fab Valve Catalogue

Overview (1MB)

Fab Valve Presentations

Overview (94.3MB)PDF (4.6MB)

Fab Valve IOM Manual

PDF (0.1MB)

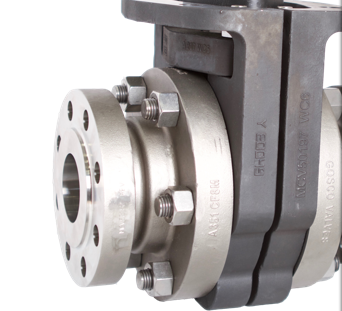

Fab Valve Overview

The Fab Valve design uses common internals for all pressure classes, and the same non-wetted horseshoe plates for bolting containment. By machining just four components, we can provide ANY combination of end connections (NPT, 150#, 300#, 600#, BW, SW & custom), port size (FP or SP), and materials of construction, including exotic alloys such as Inconel, Monel, Duplex, Hastelloy, Alloy 20 etc. Spares are minimized, delivery is fast, and you get the same Gosco quality.

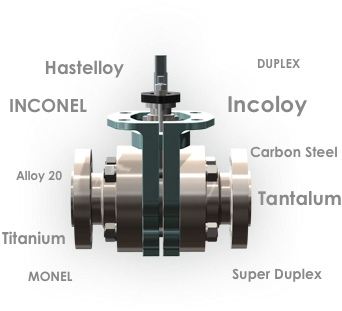

Exotic Alloys

We matched all the internals of the Fab Valve to the most corrosion resistant spring material on the market - Inconel 718. The four components that are left can be manufactured from any commercially available metal, including Hastelloy, Inconel, Titanium, Tantalum, Monel, Alloy 20, Duplex, etc. The horseshoe body plates for bolting containment never come in to contact with the process media, so they’re cast from less expensive ASTM A217 Grade WC6 material. You get an exotic alloy valve for less money, and you have the same Gosco quality.

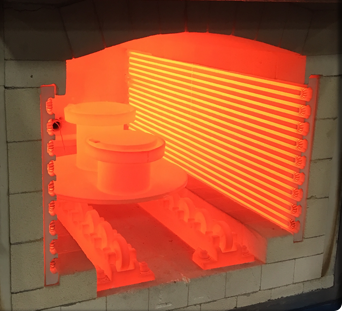

Superior Trim Hardening

BORONIZING is a thermo-chemical surface hardening process that creates a surface layer that’s so hard, it can’t be measured on the Rockwell C Scale. We use Inconel 718 because it is the best overall metal for corrosion, high temperature, and wear resistance. Our PROPRIETARY BORONIZING has a layer depth over 100 microns (0.004”) and a hardness between HV 2500-2700.

Compared to HVOF coatings, BORONIZING is:

Substantially harder, markedly more wear resistant, impervious to corrosion, and is capable of handling huge temperature shocks without spalling or flaking.Seat/Spring Design

Gosco's patented seat/spring design is perfect for powder/catalyst applications. When powder gets trapped in the spring cavity, it causes the valve to “lock up”. To solve this issue, Gosco uses a completely different approach to the competition - instead of trying to seal the spring from the media, we deliberately open up the cavity around the spring. This allows the media to flow around the spring, but also allows it to escape just as easily. Media never gets trapped in the valve, so we never have issues with valves "locking up".

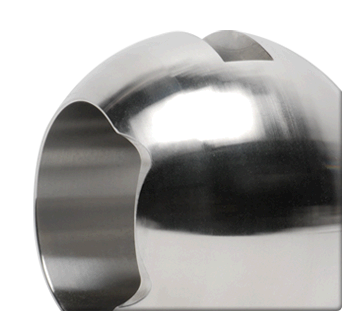

Arcuate Cut Ball

An arcuate cut is a profile in the ball that reduces velocity as the valve opens and closes. When a standard ball valve is in the first and last ten degrees of opening/closing, velocities are very high (especially in the corners), and erosion occurs. With an arcuate cut, the opening on the ball is almost three times as large. This reduces the velocity by spreading out the flow through a larger opening, which ultimately reduces wear on the ball and seats.

Bi-Directional Sealing

The Fab Valve design is completely symmetrical, and doesn't have a “Preferred Direction”. Fab Valves seal bubble tight in both directions with both a full pressure differential, or

a 1psi drop. They are completely bi-directional, so installers do not need to worry about

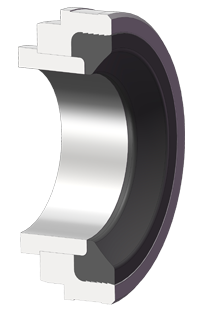

the correct flow direction and/or high pressure side, when installing the valves.Encapsulated “Soft" Seats

The Fab Valve encapsulated “Soft" seats are used for high cycle, abrasive, and high pressure/temperature applications. Our proprietary live-loaded design allows us to completely encapsulate the insert on all four sides, leaving only a small section of the "Soft" material exposed for sealing. The insert is held in place with “barbs” that prevent it from extruding out of the carrier. A special fixture compresses the seat assembly to 3 times the maximum pressure rating of the valve, so that the insert takes a compression set. The seat profile is then machined in to the insert, and it is match lapped to the ball. For abrasive applications, it can be used in conjunction with a boronized, arcuate cut ball.

Fast Track

What good is an elite custom ball valve if it can’t be delivered when you need it? Fast Track is our expedited delivery service, designed to help you meet near-impossible deadlines. The fee is calculated based on accelerated engineering & design, supplier expedite charges, air freight charges, extra manpower, and other associated costs. What does this buy you? The world’s best valve and a solid guarantee: If we don't deliver on time, we waive all Fast Track fees.