M-Class Sizes

NPS ½ FP to NPS 16 SP

½″ FP to 16″ SPM-Class Connections

150# to 4500#, NPT, SW,

BW, Grayloc and CustomM-Class Configurations

On/Off, Vari-V Control, Cryogenic, 3-Way Diverter, Double Isolation & BleedM-Class Temperatures

-200°C to 788°C

-328°F to 1450°FM-Class Delivery

Made to Order

Expedited delivery available.M-Class Quote

Click here to receive an

M-Class Valve quote.

M-Class Valve Downloads

M-Class Valve Catalogues

Overview (2MB)Printable (2.4MB)

M-Class Valve Presentations

Overview (70MB)PDF (3.6MB)

M-Class IOM Manual

IOM Manual (0.6MB)

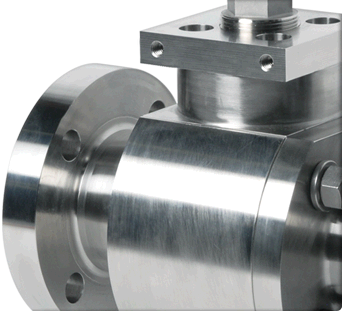

M-Class Valve Overview

M-Class is an elite line of easily customizable metal seated ball valves that outperform in every application and are designed to minimize downtime and to ensure safety for the end user. M-Class valves have specific features to deal with any combination of abrasive, corrosive, high temperature, high pressure, and high-cycle applications. Features include a proprietary trim hardening procedure, a unique actuator mounting system, truly bi-directional sealing, and Vari-V control balls & arcuate cut balls.

M-Class metal seated ball valves are widely used in mining, chemical, oil & gas, and power/energy industries.

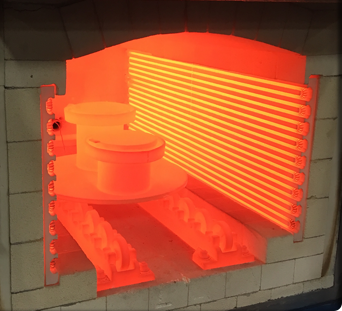

Superior Trim Hardening

BORONIZING is a thermo-chemical surface hardening process that creates a surface layer that’s so hard, it can’t be measured on the Rockwell C Scale. We use Inconel 718 because it is the best overall metal for corrosion, high temperature, and wear resistance. Our PROPRIETARY BORONIZING has a layer depth over 100 microns (0.004”) and a hardness between HV 2500-2700.

Compared to HVOF coatings, BORONIZING is:

Substantially harder, markedly more wear resistant, impervious to corrosion, and is capable of handling huge temperature shocks without spalling or flaking.Bi-Directional Sealing

The M-Class Valve design is completely symmetrical, and doesn't have a “Preferred Direction”. M-Class Valves seal bubble tight in both directions with both a full pressure differential, or a 1psi drop. They are completely bi-directional, so installers do not need to worry about flow direction and/or high pressure sides.

Seat/Spring Design

Gosco's patented seat/spring design is perfect for powder/catalyst applications. When powder gets trapped in the spring cavity, it causes the valve to “lock up”. To solve this issue, Gosco uses a completely different approach to the competition - instead of tryingto seal the spring from the media, we deliberately open up the cavity around the spring. This allows the media to flow around the spring, but also allows it to escape just as easily. Media never gets trapped in the valve, so we never have issues with valves "locking up".

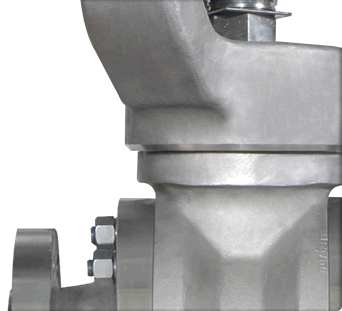

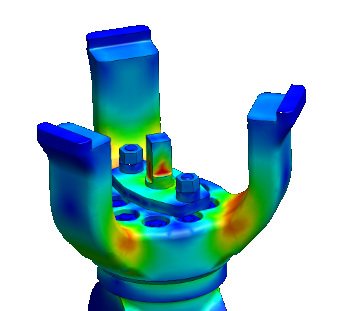

Tripod Mounting System

The M-Class Tripod Mount allows you to install the valve in any orientation without supporting the actuator, and we use Finite Element Analysis (FEA) to guarantee it. The very unique design also eliminates actuator misalignment. Three evenly-spaced prongs define a plane, preventing the actuator from rocking. When paired with a CNC machined mounting plate that cannot move left to right or back and forth, the actuator is guaranteed to be aligned correctly. Additionally, the packing can be adjusted without having to remove the actuator, and the three tripod prongs act as a heat sink to minimize the amount of heat that gets to the actuator.

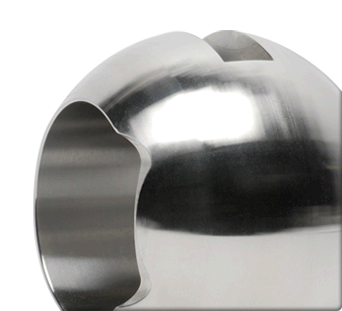

Arcuate Cut Ball

An arcuate cut is a profile in the ball that reduces velocity as the valve opens and closes. When a standard ball valve is in the first and last 10° of opening/closing, velocities are very high (especially in the corners), and erosion occurs. With an arcuate cut, the opening on the ball is almost three times as large. This reduces the velocity by spreading out the flow through a larger opening, which reduces wear on the ball and seats. BORONIZING must be used to harden arcuate cut profiles because HVOF coatings are line of sight and can not evenly coat the ball.

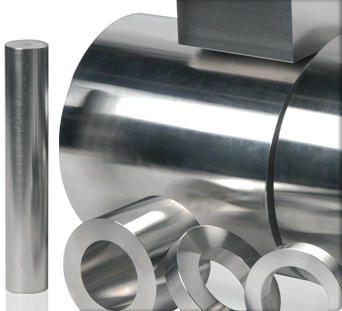

Exotic Alloys

If you can cast it, or it is available in bar stock/forgings, Gosco can create your own bespoke M-Class 3-Way Diverter Valve, even with metals that require vacuum casting (e.g. titanium). We are not restricted to making merely the body from exotic alloys, as we can manufacture all components to your exact specifications, right down to the bolting. Our engineering team at Gosco Valves has extensive experience in corrosive applications, and we can recommend the best material to use for your specific application.

Made To Order

Not all processes are the same, and applications exist where standard valves just don't cut it. Our strength is being able to find solutions to problems that other manufacturers simply don’t have the capability to solve. Gosco has a team of specialized engineers, an independent R&D facility, cutting edge design technology and decades of experience in severe service applications. We also have a “Think Outside the Box” philosophy, and a “Say Yes” attitude, so when you need a BESPOKE valve, made exactly to your specifications - you have come to the right company

Fast Track

What good is an elite custom ball valve if it can’t be delivered when you need it? Fast Track is our expedited delivery service, designed to help you meet near-impossible deadlines. The fee is calculated based on accelerated engineering & design, supplier expedite charges, air freight charges, extra manpower, and other associated costs. What does this buy you? The world’s best valve and a solid guarantee: If we don't deliver on time, we waive all Fast Track fees.