Block & Bleed Sizes

NPS ½ FP to NPS 16 SP

½″ FP to 16″ SPBlock & Bleed Connections

150# to 4500#, NPT, SW,

BW, Graylock and CustomBlock & Bleed Applications

Customizable with a bubble tight seal, exotic alloys, & custom endsBlock & Bleed Temperatures

-50°C to 260°C

-58°F to 500°FBlock & Bleed Delivery

Standard Delivery (16-20 weeks)

Expedited delivery available.Block & Bleed Quote

Click here to receive a

Block & Bleed Valve quote.

S-Class Valve Downloads

S-Class Valve Catalogue

Overview (7.3MB)

S-Class Valve Presentations

Overview (40.4MB)PDF (8.9MB)

S-Class Valve IOM Manual

IOM Manual (0.9MB)

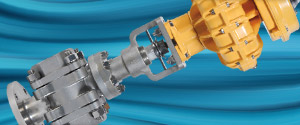

Block & Bleed Valve Overview

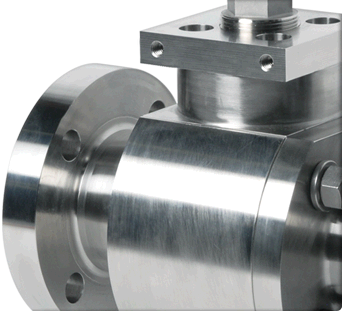

The Gosco Block and Bleed valve combines all the unique features in a standard S-Class valve with encapsulated seats that are not only live loaded, but also truly bi-directional.

Block & Bleed

This makes the Gosco a true Double Isolation and Bleed valve. With the best shaft sealing system in the world, any exotic alloy option and high pressure capabilities (up to Class 4500), these valves are versatile enough to tackle the toughest applications.Configurations

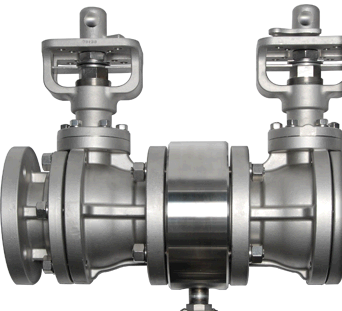

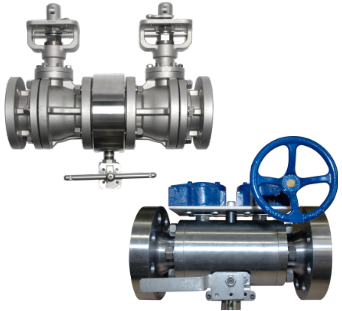

The Gosco Block & Bleed valve is essentially two bi-directional valves with a bleed valve between them. We offer two options: two valves with a spacer/bleed valve between them,

Configurations

or an integral body with two internal valves and a bleed valve. Both options meet all definitions of API 6D for double block & bleed (DBB) and double isolation & bleed (DIB),

as well as OSHA double block & bleed (DBB).Shaft Sealing

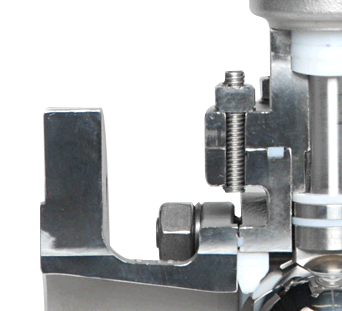

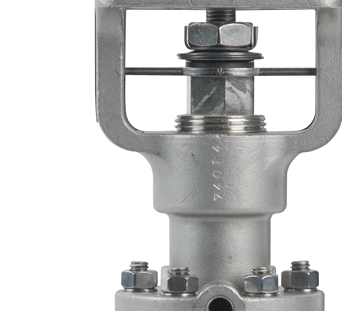

The core of our patented shaft sealing system is the dual live-loaded packing. To eliminate side loading on the packing, we've added two shaft guides to support the shaft at the bottom and the top. For a third layer of protection, a fugitive emissions port can be drilled to monitor the areas between the packing sets. Our shaft sealing system has been tested by TUV, and exceeds all current and projected fugitive emission standards.

Shaft SealingBi-Directional Sealing

To meet all definitions of block & bleed valves (BB, DBB, DIB and OSHA DBB), the block valves MUST have bi-directional sealing at full design pressures, and at a 1psi differential. S-Class block & bleed valves use live-loaded encapsulated seats to accomplish this. That means we can offer you any type of block & bleed valve. The difficulty is finding out what type you really need.

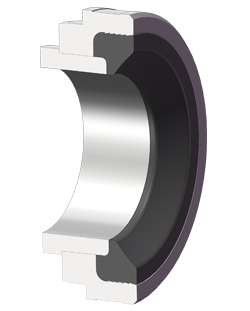

Bi-DirectionalEncapsulated "Soft" Seats

S-Class encapsulated soft seats are used for high cycle, abrasive, and high pressure/temperature applications. Our proprietary live-loaded design allows us to completely encapsulate the insert on all four sides, leaving only a small section of the "Soft" material exposed for sealing. The insert is held in place with “barbs” that prevent it from extruding out of the carrier. A special fixture compresses the seat assembly to 3 times the max pressure rating of the valve, so that the insert takes a compression set. The seat profile is then machined in to the insert, and it is match lapped to the ball. For abrasive applications, it can be used in conjunction with a boronized, arcuate cut ball.

Encapsulated SeatsExotic Alloys

Cast, forged or bar stock, Gosco manufactures ball valves out of any metal - even specialty metals that require vacuum casting (like titanium). We are not restricted to making just the body from exotic alloys - we can manufacture any component to suit your needs, right down to the bolting. Our engineering team at Gosco Valves has extensive experience in corrosive applications, and can recommend the appropriate material to use for specific media.

Exotic AlloysExtended Bonnet

The extended bonnet is perfect for insulated lines as there is at least 2" between the top of the flange and the bottom of the Clearview mounting pad. This allows you to fully insulate the valve and still have access to make packing adjustments, without having to remove the actuator or insulation. The valve shaft flats are also visible, and the actuator is raised away from the elevated process temperatures, preventing damage to the actuator seals.

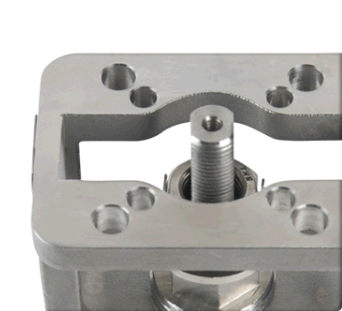

Extended BonnetClearview Mounting Pad

The Clearview mounting pad is a combination of an ISO 5211 mounting pad for easy installation of valve accessories, and a CNC machined/cast bracket that guarantees accurate actuator alignment. Packing adjustments can be performed in-line without removing the actuator, and the double "D” shaft gives you a visible indication of the position of the valve. Clearview also raises the actuator away from the valve, and acts as a heat sink to protect it from high temperatures.

ClearviewFast Track Service

What good is an elite custom ball valve if it can't be delivered when you need it? Fast Track, our expedited delivery service is designed to help you meet near-impossible deadlines. The fee is based on accelerated engineering and design, supplier expedite charges, air freight, extra manpower and other associated costs. What does this buy you? The best custom ball valve and a solid guarantee: if we don't deliver on time, we will waive all Fast Track fees.

Fast Track